Laser Cleaning of Stone and Masonry

This article attempts to answer the following questions regarding laser cleaning of stones and masonry:

• Are laser cleaning systems ready and appropriate to take care of stone and masonry?

• What are the advantages and paybacks of laser stone cleaning?

• What are the possible mistakes that can be inflicted by laser cleaning?

• Under which conditions the stone is damaged by laser cleaning?

• How different types of stones react to the laser pulse?

• What is the future of laser stone cleaning?

Laser cleaning is a gift of the Physics community to help preserve historical structures. Air pollution and particularly sulfuric acid aerosols interact with calcium carbonate statues to form a layer of gypsum which is made of calcium sulfate and water. Laser cleaning can be used to remove film deposits and contaminants such as sulfates and nitrates from marble structures. Figure 1 below shows a statue with a dark deposit on it.

Figure 1: Pollution accumulation on an outdoor statue

When one compares laser cleaning with other stone cleaning methods, the former stands out due to its accuracy, non-contact implementation and its versatility. Laser cleaning’s wide usage was initially suppressed due to some skepticism of it being a complex method and limitation in accessing the original monuments for testing purposes. However, improvements in modeling of laser pulse interactions with stone and technological advances in laser systems overcame these initial doubts and laser cleaning has emerged as a front runner for cleaning historical monuments. So to address the first two questions posed at the beginning of the article, one can answer that pulsed laser systems such as Nd:YAG lasers at 1064 nm with the use of their harmonic wavelengths are ready to be used for stone cleaning. Other types of pulsed laser with adjustable pulse widths could also be used. As for the advantages of the laser cleaning as compared to sandblasting, scrubbing, chemical methods and ultra-sonics, the non-contact method and accuracy in removing the deposited film can be named.

To answer the third, fourth and fifth questions which are all related together, one has to consider the nature of laser pulse interaction with the stone. The interaction of laser pulse with the stone can be classified into self-limiting and non-self-limiting laser ablation processes. In case of self-limiting laser ablation processes, the damage threshold of the deposited contaminant film is way below that of the underlying substrate. On the other hand for non-self-limiting laser ablation processes the damage thresholds of both the substrate and the film are very close to each other. As a result in the former case, the cleaning process is much easier because if the appropriate laser pulse energy and duration (the term laser fluence is widely used which means energy per unit area and the unit is joules/cm2) is used the contaminant film is evaporated way before a damage to the underlying substrate is inflicted. For the non-self-limiting case the possibility of damage is much higher.

Figure 2: Laser cleaning of marble statues is important for aesthetic reasons and restoration

Figure 3: laser cleaning of artwork

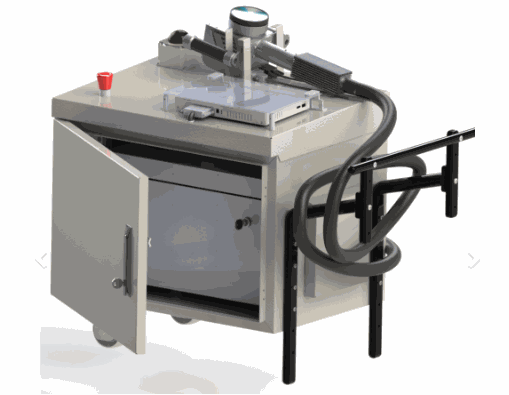

Figure 4: Laser Art system by Allied Scientific Pro

This laser cleaning system is very robust and has a long lifetime without maintenance. The 100 Watt of power produced by the laser which is directed by a fiber towards the stone structure is capable of removing the most stubborn stains. The beam shape is also controllable using a galvo system and lens combination to suite different styles of the stone structure.

As to the final question posed at the beginning of the article, more studies need to be done to understand the effect of crystallographic defects and self-focusing in laser particle interaction to avoid inflicting damage to the underlying substrate better.

A table comparing laser cleaning with other techniques follows:

Table 1: Comparison of Cleaning Techniques

Visit our dedicated Laser Cleaning Website to learn more

References:

1- Laser cleaning of stone material: An overview of current research, Carlos Rodrigues Navarro et al. Studies in Conservation, 48:sup1, 65-82.

2- Laser cleaning in conservation of stone, metal, and painted artifacts: State of the art and new insights on the use of Nd:YAG laser. S. Siano et al. Applied Physics A · February 2012.